laser cutting services dubai has revolutionized the manufacturing and design industries, offering unparalleled precision and versatility. In Dubai, a city known for its innovation and rapid development, laser cutting services have become essential for various applications, from industrial fabrication to creative arts. This article explores the top laser cutting service providers in Dubai, highlighting their capabilities, the range of materials they work with, and how they cater to the diverse needs of businesses and individuals in this dynamic city.

what is laser cutting

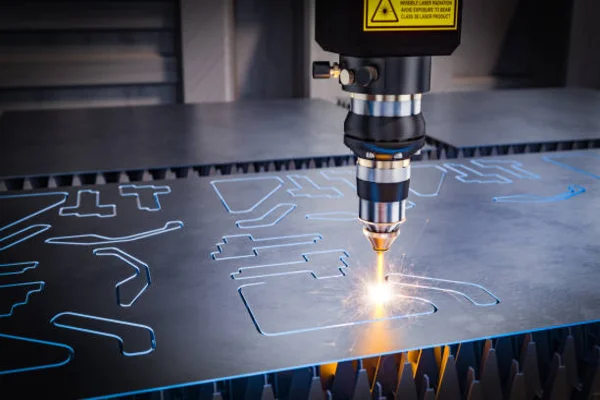

Laser cutting is a manufacturing process that uses a high-powered laser beam to cut, shape, or engrave materials. The laser beam is directed onto the material, which is typically metal, wood, plastic, or fabric, to produce precise cuts or intricate designs.

Here’s a breakdown of how laser cutting works and its applications:

see more about our laser cutting services

How Laser Cutting Works

- Laser Generation:

A laser source (e.g., CO2, fiber, or Nd

laser) generates a focused beam of light.

- Beam Focusing:

The laser beam is directed through a series of mirrors and lenses that focus it onto a small, precise spot on the material’s surface.

- Material Cutting:

The focused laser beam heats and melts the material in the localized area. The cutting path is controlled by computer numerical control (CNC), allowing for intricate and accurate cuts.

- Assist Gases:

Assist gasses such as nitrogen, oxygen, or air are often used to blow away the molten material and help achieve a cleaner cut.

Types of Laser Cutting

- CO2 Laser Cutting:

Effective for cutting, engraving, and boring. Commonly used for non-metallic materials like wood, acrylic, glass, and fabrics.

- Fiber Laser Cutting:

Uses a solid-state laser and is efficient for cutting metals like stainless steel, aluminum, and brass. Known for high-speed and precision cutting.

- Nd Laser Cutting:

Typically used for engraving and marking metals and some plastics.

contact us and have your service

What is laser cutting used for?

Manufacturing: Cutting parts for machinery, automotive components, and electronic devices.

Art and Design: Creating intricate designs in jewelry, decorative items, and architectural models.

Signage: Producing detailed signs and lettering.

Prototyping: Rapidly creating prototypes with high precision and detail.

Textiles: Cutting and engraving fabrics for fashion and upholstery.

Advantages of Laser Cutting

Precision: Extremely high accuracy and ability to create intricate designs.

Speed: Fast cutting process, especially for complex shapes.

Versatility: Capable of cutting a wide range of materials.

Quality: Produces clean cuts with minimal distortion or need for post-processing.

Automation: Can be easily integrated with CNC for automated and repeatable processes.

Limitations of Laser Cutting

- Material Thickness:

Limited to relatively thin materials for cutting.

- Cost:

Initial investment in laser cutting equipment can be high.

- Material Suitability:

Not all materials can be cut with a laser (e.g., certain reflective metals).

laser cutting services dubai

Sama Al-Samha is a notable provider of laser cutting services in Dubai.

They are known for their high-quality work, precision, and the ability to handle a variety of materials and projects.

Here are some key details about their services:

Services Offered:

- Laser Cutting:

Precision cutting for a variety of materials including metal, wood, acrylic, fabric, and more.

- Engraving:

Detailed engraving services for personalization and intricate designs.

- Marking:

Industrial marking for parts, tools, and other applications.

Materials:

Metals (steel, aluminum, brass, etc.)

Wood and MDF

Acrylic and other plastics

Fabric and leather

Glass

Applications:

Industrial parts and components

Custom signage and displays

Decorative items and art pieces

Prototyping and model making

Personalized gifts and crafts

For specific inquiries, project consultations, and quotes, it’s best to contact Sama Al-Samha directly through their website or customer service channels.

Custom laser cutting for you

Sama Al-Samha offers tailored laser cutting services to meet the unique needs of clients across various industries. Here’s a detailed look at what they offer:

- Key Features

Precision and Quality

- High-Precision Cutting: Utilizing advanced laser technology to achieve precise cuts with minimal material wastage.

- Clean Edges: Producing clean, smooth edges that often require no further finishing.

Customization Options

- Design Flexibility: Capable of handling complex designs and intricate patterns, ideal for custom projects.

- Prototyping and Production: Suitable for both small-scale prototypes and large-scale production runs.

- Personalization: Custom engraving and marking services for personalized items and branding.

Applications

- Industrial: Parts and components for machinery, automotive, and electronics.

- Signage: Custom signs, logos, and displays for businesses and events.

- Decorative: Art pieces, architectural models, and interior decor.

- Retail: Custom products, promotional items, and packaging.

- Fashion: Cutting and engraving for textiles, leather goods, and accessories.

Benefits of Choosing Sama Al-Samha

- Expertise: Experienced team capable of delivering high-quality results.

- Technology: State-of-the-art laser cutting equipment ensuring precision and efficiency.

- Customer Support: Dedicated customer service to assist with design, material selection, and project management.

- Quick Turnaround: Efficient processes to meet tight deadlines without compromising on quality.

Laser cutting prices

The cost of laser cutting services can vary widely based on several factors, including the complexity of the design, the type of material, the thickness of the material, the quantity of pieces, and the specific service provider.

Here’s a breakdown of what generally influences laser cutting prices:

- Factors Affecting Laser Cutting Prices

Material Type

- Metals:

Typically more expensive due to higher material costs and the need for more powerful lasers.

- Non-Metals:

Materials like acrylic, wood, and fabric tend to be less expensive.

Material Thickness

Thicker materials require more laser power and time, increasing the cost.

Design Complexity

- Intricate designs with detailed cuts or engravings take longer to process and may incur higher costs.

- Simple, straightforward cuts are typically less expensive.

Quantity

- Bulk orders can often be processed more efficiently, leading to lower per-unit costs.

- Single or small batch orders may be more expensive per unit.

- Setup and Preparation

- Initial setup, design adjustments, and file preparation can add to the cost.

- One-time setup fees might apply for custom projects.

In the end, laser cutting services dubai stand out for their precision, versatility, and ability to cater to a wide range of industries and creative projects. From intricate designs and custom signage to precise industrial components, these services harness advanced technology to meet the diverse needs of the city’s dynamic market.

With expert providers like Sama Al-Samha and others, businesses and individuals can achieve exceptional results, transforming their ideas into reality with efficiency and high quality.

As Dubai continues to grow and innovate, its laser cutting services will remain at the forefront, driving creativity and manufacturing excellence. contact us now