Sama Al Samha metal fabrication dubai

The metal fabrication dubai plays a crucial role in the region’s rapidly growing construction and manufacturing sectors. As a hub for innovation and development, Dubai boasts a wide range of metal fabrication services that cater to various industries, including architecture, engineering, and automotive. This article explores the key aspects of metal fabrication in Dubai, highlighting the techniques used, the benefits of custom solutions, and the leading companies in the field.

Guide to best Metal Fabrication Dubai company

metal fabrication dubai

When it comes to metal fabrication in Dubai, Sama Al-Samha stands out as a top choice for businesses and individuals seeking high-quality services.

For anyone seeking reliable and high-quality metal fabrication services in Dubai, Sama Al-Samha is undoubtedly a top contender.

With their comprehensive range of services, commitment to quality, advanced technology, and customer-focused approach, they are well-equipped to handle projects of all sizes and complexities.

Whether you’re in construction, manufacturing, or any other industry that requires metal fabrication, Sama Al-Samha is your go-to partner for success.

read more: company for metal fabrication uae

Metal Fabrication Techniques Used in sama al samha

Sama Al-Samha employs a variety of advanced metal fabrication techniques to ensure high-quality results tailored to their clients’ needs.

So here are some key techniques they utilize:

-

CNC Machining

We could say that CNC machining is a manufacturing method that utilizes computer-controlled machines to operate tools like mills, lathes, routers, and grinders.

These machines are programmed to precisely cut, shape, and manufacture parts from materials such as metal, plastic, or wood.

CNC machining is highly automated, providing precision and efficiency in producing intricate components with little manual input, making it widely used in industries like aerospace, automotive, and electronics.

read more: company for cnc cutting dubai

-

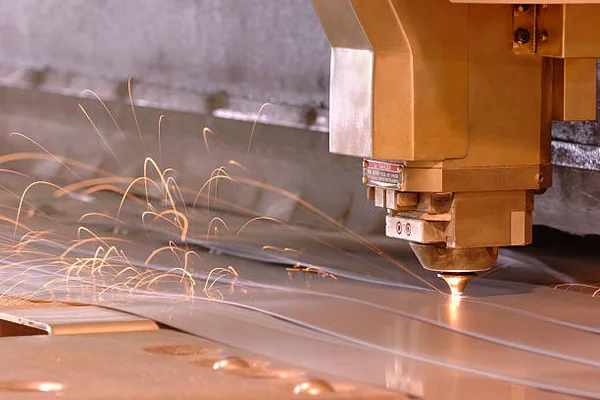

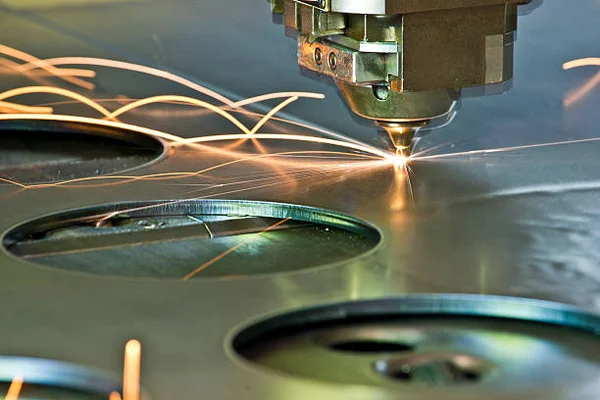

Laser Cutting

Sama Al-Samha uses state-of-the-art laser cutting technology to create intricate shapes and patterns in metal.

This method provides clean edges and minimal material waste, making it suitable for detailed work.

read more: Get best laser cutting services dubai

-

Welding

Expert welding services are a cornerstone of their fabrication process.

They utilize various welding techniques, including MIG, TIG, and spot welding, to join metal pieces securely.

This ensures the structural integrity and durability of the final products.

-

Sheet Metal Fabrication

This technique involves the cutting, bending, and shaping of sheet metal to create components used in various applications.

Sama Al-Samha specializes in producing custom sheet metal parts tailored to specific project requirements.

-

Metal Forming

Metal forming techniques, such as bending and rolling, are employed to shape metal into desired forms without cutting.

This process is essential for creating items like brackets, frames, and other structural components.

-

Surface Treatment

To enhance durability and appearance, Sama Al-Samha provides various surface treatment options, including powder coating, painting, and galvanizing.

These treatments help protect against corrosion and improve the overall finish of the metal products.

-

Assembly Services

In addition to fabrication, Sama Al-Samha offers assembly services for metal components.

This ensures that all parts fit together correctly and function as intended, streamlining the production process for clients.

Sama Al-Samha’s use of these advanced metal fabrication techniques not only guarantees high-quality results but also positions them as a leader in the industry. Their commitment to precision, efficiency, and customer satisfaction makes them a preferred choice for various metal fabrication projects in Dubai.

why you choose us as the Right Metal Fabrication Company in Dubai

Choosing Sama Al-Samha as the right metal fabrication company in Dubai comes with several compelling advantages:

- Expertise and Experience

With years of experience in the industry, our skilled team has a deep understanding of metal fabrication techniques and best practices, ensuring high-quality results for every project.

- Advanced Technology

We invest in state-of-the-art equipment and technology, including CNC machining and laser cutting, which enhance precision and efficiency.

This allows us to handle both complex designs and large-scale production with ease.

- Custom Solutions

At Sama Al-Samha, we understand that each project is unique.

We work closely with our clients to provide tailored solutions that meet their specific needs, from initial design to final production.

- Quality Assurance

We are committed to maintaining the highest quality standards throughout the fabrication process.

Our rigorous quality control measures ensure that every product meets or exceeds industry standards.

- Customer-Centric Approach

Our focus on customer satisfaction means we prioritize open communication and responsiveness.

We keep clients informed at every stage of the project and are always ready to address any concerns.

- Competitive Pricing

We offer competitive pricing without compromising on quality, providing detailed quotations to help clients stay within their budgets while receiving top-notch fabrication services.

- Sustainability Practices

Sama Al-Samha is dedicated to environmentally friendly practices, using recyclable materials and minimizing waste during production, aligning with modern sustainability goals.

- Positive Reputation

Our commitment to excellence has earned us a strong reputation in the industry, backed by positive client testimonials and a track record of successful projects.

By choosing Sama Al-Samha, you’re partnering with a reliable and innovative metal fabrication company that prioritizes quality, efficiency, and customer satisfaction in every project.

Quality Control in Metal Fabrication

metal fabrication dubai

The quality control in metal fabrication is essential to ensure that products meet specifications and standards.

The key aspects include:

- Material Inspection:

Checking raw materials for defects and compliance with standards before use.

- Process Monitoring:

Continuously overseeing fabrication processes to maintain precision and consistency.

- Dimensional Checks:

Measuring components during and after fabrication to ensure they meet required dimensions.

- Welding Inspections:

Evaluating weld quality through visual checks and non-destructive testing.

- Surface Finish Assessment:

Checking for defects in the surface finish to ensure durability and appearance.

- Final Product Testing:

Conducting tests on finished products to confirm they meet performance standards.

- Documentation:

Keeping records of inspections and tests for traceability and compliance.

By implementing these quality control measures, companies can ensure high-quality, reliable metal products that satisfy customer expectations.

best Custom Metal Fabrication Options

When considering custom metal fabrication, several options stand out for their versatility and quality.

And here are some of the best options:

- CNC Machining:

Provides precise cutting and shaping for complex designs.

- Laser Cutting:

Offers high precision and clean edges for intricate shapes.

- Metal Stamping:

Efficient for producing large quantities of identical parts.

- Welding:

Creates strong joints for metal assemblies using various techniques.

- Sheet Metal Fabrication:

Involves cutting and shaping sheet metal for enclosures and ductwork.

- 3D Metal Printing:

Allows for complex geometries that traditional methods can’t achieve.

- Forming and Bending:

Techniques to create specific shapes and curves in metal.

- Surface Finishing:

Enhances durability and appearance through treatments like powder coating.

Each option has its advantages, so the best choice depends on your project’s specific needs.

Finally,metal fabrication dubai is an essential industry that supports the city’s dynamic growth and development. With a variety of advanced techniques and skilled companies available, businesses can find tailored solutions to meet their specific needs. Whether it’s for construction, manufacturing, or custom projects, the quality and innovation present in Dubai’s metal fabrication sector ensure that clients receive high-quality products. As the industry continues to evolve, staying informed about the latest trends and services will help you make the best choices for your projects.