prefabricated mezzanine system

prefabricated mezzanine system are innovative solutions designed to maximize vertical space in industrial, commercial, and retail environments. These modular structures provide a cost-effective way to expand usable space without the need for extensive construction or relocation.

What is a Prefabricated Mezzanine System?

A prefabricated mezzanine system is a pre-engineered, modular structure designed to create additional floor space within an existing building.

Made primarily of steel, these systems are manufactured off-site, allowing for quick and efficient on-site installation.

They are versatile and customizable, making them ideal for warehouses, factories, offices, and retail spaces.

Prefabricated mezzanines maximize vertical space without the need for extensive construction, providing cost-effective and durable solutions for expanding usable areas.

Benefits of Installing Mezzanine Systems in Industrial Spaces

Installing a prefabricated mezzanine system is a smart investment for industrial spaces looking to enhance functionality and optimize their operations.

So here are the benefits of installing Mezzanine Systems in industrial spaces:

- Maximizes Space Utilization

Mezzanine systems effectively use vertical space, allowing businesses to create additional storage or operational areas without expanding the building footprint.

- Cost-Effective Expansion

Compared to constructing a new facility, installing a mezzanine is a more affordable option for increasing usable space while avoiding relocation or major renovations.

- Customizable and Flexible

This prefabricated mezzanine system can be tailored to meet specific needs, such as load capacity, layout, and purpose, making them ideal for warehouses, production areas, and offices.

- Quick Installation

Prefabricated mezzanine systems are easy to assemble, minimizing downtime and ensuring a faster transition to improved operational efficiency.

- Improves Workflow Efficiency

By creating dedicated spaces for storage, production, or administrative tasks, mezzanines streamline processes and improve overall productivity.

- Durable and Long-Lasting

Made of high-quality steel, mezzanine systems are robust, ensuring they can withstand heavy loads and prolonged industrial use.

Industries Utilizing Prefabricated Mezzanine Systems

Prefabricated mezzanine systems are versatile and widely used across various industries to optimize vertical space and improve efficiency.

From warehousing to retail, these systems provide cost-effective solutions for expanding functionality within existing facilities.

- Warehousing and Logistics

prefabricated mezzanine system is widely used in warehouses to increase storage capacity, organize inventory, and create dedicated picking or packing areas without expanding the facility.

- Manufacturing

Manufacturers rely on mezzanine systems for additional production space, equipment storage, or assembly lines, ensuring efficient use of vertical space.

- Retail

Retailers use mezzanines to display products, create office spaces, or expand storage areas, optimizing their floor layout for better customer experience and inventory management.

- Automotive

The automotive industry uses mezzanines for spare parts storage, vehicle maintenance stations, or as dedicated workspaces for specialized equipment.

- Aerospace

In aerospace, mezzanines are essential for tool storage, assembly operations, and managing large equipment in hangars or production facilities.

- Food and Beverage

Mezzanine systems help food processing plants and beverage companies maximize storage for raw materials, packaging, and finished goods, ensuring streamlined workflows.

- Pharmaceuticals

Pharmaceutical companies use mezzanines to create clean storage areas, packaging zones, or administrative offices within their facilities.

- E-commerce

E-commerce businesses utilize prefabricated mezzanine system for order fulfillment, inventory management, and sorting operations, improving efficiency in high-volume facilities.

Prefabricated mezzanine systems are versatile solutions for various industries, helping businesses enhance space utilization and operational efficiency.

Materials Used in Mezzanine Fabrication

Mezzanine systems are constructed using a variety of durable materials to ensure strength, functionality, and longevity.

The most common materials include:

- Steel

Steel is the primary material for mezzanine fabrication due to its exceptional strength, durability, and load-bearing capacity. It is ideal for industrial and commercial applications requiring heavy-duty support.

- Aluminum

Aluminum is used for lightweight mezzanine structures where mobility or corrosion resistance is a priority, such as in specific manufacturing or cleanroom environments.

- Composite Materials

Composite materials combine the benefits of steel, wood, or concrete, offering strength and design flexibility for unique mezzanine requirements.

Each material is selected based on the specific needs of the application, ensuring the mezzanine meets structural and functional demands effectively.

Design Considerations for Prefabricated Mezzanines

When designing a prefabricated mezzanine, several critical factors must be considered to ensure safety, functionality, and efficiency:

- Load Capacity

Determine the weight the mezzanine will need to support, including equipment, storage, and personnel, to select materials and structural reinforcements that meet safety standards.

- Space Utilization

Plan the layout to optimize vertical and horizontal space while allowing for easy movement and accessibility within the existing structure.

- Building Regulations

Ensure compliance with local building codes, fire safety regulations, and industry standards to guarantee legal and safe installation.

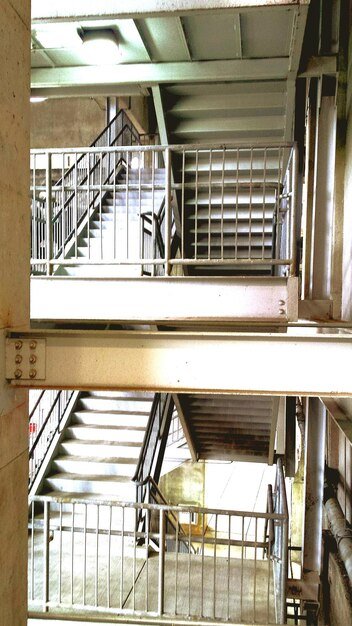

- Access Points

Incorporate stairs, ladders, or lifts strategically to provide safe and convenient access to the prefabricated mezzanine system while maintaining workflow efficiency.

- Flooring Type

Select the appropriate flooring material, such as steel grating, wood, or concrete, based on the intended use and load requirements.

- Integration with Existing Systems

Design the mezzanine to seamlessly integrate with existing equipment, lighting, ventilation, and workflow processes without disruptions.

- Future Expandability

Consider modular designs that allow for future expansion or reconfiguration to adapt to changing operational needs.

Prefabricated mezzanines must be thoughtfully designed to maximize functionality and safety, making them a valuable investment for any industrial or commercial space.

Read more: Best prefabricated steel mezzanines

Cost Analysis of Mezzanine System

Understanding the costs involved in a mezzanine system helps businesses budget effectively.

Here are the main factors influencing the cost:

- Material Costs

The type of material used, such as steel, aluminum, or wood, significantly affects the overall price. Steel is the most common but tends to be more expensive due to its strength and durability.

- Size and Design

The dimensions, load capacity, and complexity of the mezzanine design impact costs. Larger and custom-designed mezzanines generally incur higher expenses.

- Flooring Type

The choice of flooring material, whether steel grating, wood, or concrete, contributes to the variation in cost based on durability and usage requirements.

- Installation Costs

Labor charges for assembling and installing the mezzanine vary depending on the project’s complexity and the required time. Prefabricated systems can reduce these costs.

- Compliance and Permits

Costs may include obtaining necessary building permits and ensuring the design meets local building and safety regulations.

- Additional Features

Optional features like handrails, stairs, lifts, or integrated lighting and ventilation systems increase the overall expense.

Maximizing Value

Investing in a high-quality mezzanine system, such as those provided by Sama Al-Samha, ensures durability and long-term cost efficiency.

For tailored solutions that suit your budget and requirements, reach out to a trusted provider today.

Finally, prefabricated mezzanine system is a practical and efficient way to optimize space and improve functionality in various settings. Their versatility, durability, and ease of installation make them a smart investment for businesses looking to expand. For high-quality mezzanine solutions tailored to your needs, consider partnering with Sama Al-Samha for exceptional results.

Contact us now

Read more:

Everything You Need to Know About Prefab Mezzanine Structures for Optimal Space Utilization